Underlayment

Stainmaster Underlayment

- Enhances flooring durability and longevity

- Provides essential moisture barrier protection

- Reduces noise in multi-level buildings

- Smooths out subfloor imperfections

- Improves thermal insulation and comfort

- Ideal for vinyl plank flooring

- Crucial layer beneath all roofing

- Prevents tile cracking and shifting

- Increases comfort under laminate floors

- Acts as sound-dampening underlayment

- Essential for radiant heat systems

- Helps resist mold and mildew growth

- Available in various material types

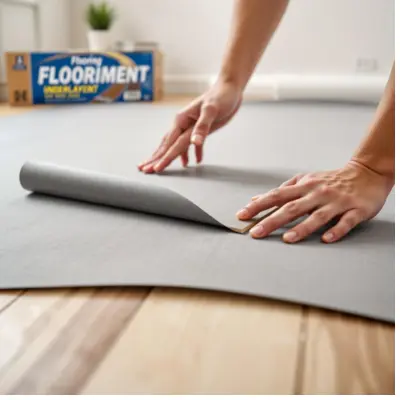

- Easy DIY installation for homeowners

- Supports heavy traffic flooring areas

- Recommended for below-grade installations

- Compatible with all flooring types

- Lightweight and easy to handle

- Required for building code compliance

- Boosts energy efficiency in homes

When it comes to flooring and roofing projects, one crucial yet often overlooked component is the underlayment. This hidden layer, placed between the subfloor or roof deck and the finished surface, plays a pivotal role in performance, durability, and comfort. Whether you’re installing vinyl, laminate, tile, carpet, hardwood, or upgrading your roofing system, the right underlayment can dramatically enhance the outcome.

What Is Underlayment?

Underlayment is a thin material laid between the base surface and the finished flooring or roofing material. Its primary functions vary depending on the application but generally include moisture protection, sound reduction, insulation, and providing a smoother, more even surface for installation. Available in a range of materials including foam, cork, rubber, plywood, and synthetic composites underlayment is tailored to meet the specific demands of various surfaces and environments.

Types of Underlayment

1. Flooring Underlayment:

For floors, underlayment improves comfort underfoot, reduces sound transmission, and prevents moisture intrusion.

Vinyl Flooring Underlayment: Ideal for luxury vinyl plank (LVP) and vinyl tile, this type often includes a vapor barrier to resist moisture from concrete subfloors.

Laminate Flooring Underlayment: Designed to cushion and reduce noise, it may also contain a moisture barrier to protect against spills and subfloor dampness.

Hardwood Floor Underlayment: A specialized barrier to prevent warping due to moisture while enhancing acoustics and providing minimal give for a natural feel.

Tile Underlayment: Offers crack isolation and waterproofing, ensuring a long-lasting, stable tile installation.

Carpet Underlay: Typically made of foam or rubber, carpet underlayment adds plushness and prolongs carpet life.

Cork Underlayment: Naturally antimicrobial and sound-absorbing, cork is often used in multifamily homes or commercial spaces where sound dampening is a priority.

2. Roofing Underlayment:

This layer provides an added level of weather protection beneath the roofing materials. It helps prevent leaks and provides additional insulation.

Synthetic Roof Underlayment: Lightweight, tear-resistant, and quick to install, synthetic options are rapidly replacing traditional felt underlayments.

Peel and Stick Roof Underlayment: Self-adhering and waterproof, ideal for vulnerable areas like valleys, eaves, and ridges.

Metal Roof Underlayment: Needs to withstand higher temperatures and often includes a reflective surface to improve energy efficiency.

Self-Leveling Underlayment: Though not typically a roofing product, this refers to a floor-prep solution that ensures an even base for finished flooring.

Key Features and Benefits

Moisture Protection: Moisture barrier underlayment protects flooring from subfloor dampness, which is crucial in basements and areas with high humidity.

Sound Reduction: Acoustic underlayments, such as quiet walk or cork varieties, reduce impact and airborne noise, especially important in multi-story buildings.

Thermal Insulation: Some products improve thermal insulation, contributing to better energy efficiency and comfort year-round.

Subfloor Smoothing: Especially for older or uneven substrates, underlayment smooths out minor imperfections and ensures a flawless installation.

Mold and Mildew Resistance: Advanced materials include antimicrobial properties that prevent the growth of mold and mildew, especially in high-moisture areas.

Application Areas

Underlayment for Laminate Floors: Choose underlays with integrated moisture barriers for added protection against spills.

Vinyl Plank Flooring Underlayment: LVP installations benefit from foam or felt underlayment with vapor control features.

Tile Underlayment: Use cement-based boards or roll-out membranes to guard against cracking and shifting.

Underlayment Plywood: Serves as a base layer when additional structural support is needed.

Roofing Applications: From asphalt shingles to standing seam metal, underlayment provides crucial backup defense against leaks.

Choosing the Right Underlayment

Selecting the correct underlayment is essential for optimal performance. Consider the type of finished surface, the location (above or below grade), environmental conditions, and the specific benefits you’re seeking like noise reduction or moisture protection.

For basements or bathrooms, vapor barrier underlayment is a must.

In bedrooms or offices, sound-reducing underlay helps maintain a quiet environment.

On rooftops in hot climates, synthetic or reflective roofing underlayment enhances energy efficiency.

E-Commerce Ready Product Positioning

When shopping online, homeowners and contractors should look for clear indicators of compatibility labels like “underlayment for vinyl flooring,” “underlayment for laminate floors,” or “synthetic roof underlayment” help streamline the selection process. Products should list core features: moisture barrier, thickness, coverage per roll, and suitable floor types.

| Model | UltraQuietPro ULP-100 |

| Finish | Smooth Fiber-Textured Surface |

| Material | Closed-Cell Polyethylene Foam with Vapor Barrier |

| Product Type | Underlayment Roll-Multi-Floor Compatibility |

| Dimensions | Roll Size: 3 ft. W x 30 ft. L Coverage: 90 sq. ft. per roll Thickness: 2 mm |

| Application Method | Loose lay or tape-to-seam depending on subfloor type |

| Surface Compatibility | Compatible with laminate, luxury vinyl plank (LVP), engineered hardwood, and rigid core flooring |

| Moisture Protection | Includes integrated vapor barrier to block moisture from below |

| Sound Rating | IIC Rating: 71 STC Rating: 66 (Excellent sound absorption for multi-level units) |

| Thermal Insulation | Provides a thermal layer that improves floor warmth underfoot |

| Subfloor Compatibility | Works over wood, concrete, plywood, and radiant-heated subfloors |

| Installation Location | Above grade, on grade, or below grade installations |

| Edge Design | Pre-marked gridlines for easy trimming and alignment |

| Additional Features | Antimicrobial treated to resist mold and mildew Reduces floor noise and footfall echo Helps smooth out minor subfloor imperfections |

| Care & Maintenance | Store in a dry place before installation. Keep dry and covered during use. |

| Country of Origin | Manufactured in North America under ISO quality control standards |

Choosing the right underlayment isn’t just about performance it’s also about long-term peace of mind. A reliable warranty ensures that your flooring or roofing underlayment investment is protected from defects in materials and workmanship, while also confirming that the product meets strict quality standards.

Most premium Stainmaster underlayment products come with warranties ranging from limited 10-year coverage to lifetime protection, depending on the material type and application. For example, underlayments designed for use with vinyl plank, laminate, hardwood, or tile flooring often include multi-decade warranties that cover product integrity, moisture resistance, and compressive strength under normal residential use. In roofing applications, synthetic underlayment may include warranties that protect against UV exposure, weathering, and tear resistance for up to 50 years.

To maintain warranty coverage, it’s critical that the underlayment be installed according to manufacturer guidelines and used with compatible flooring or roofing materials. Misuse, improper storage, or exposure to conditions beyond recommended specifications can void the warranty. Always retain purchase receipts and installation records, as they may be required for warranty claims.

Online shoppers should look for clearly stated warranty terms on product pages. Key phrases like “limited lifetime warranty”, “moisture barrier guarantee”, or “coverage against delamination” are indicators of a trustworthy product. Warranty-backed underlayment not only builds buyer confidence but also reflects the product’s engineering quality and durability.

Ultimately, a strong underlayment warranty means long-term protection, fewer unexpected repair costs, and lasting performance beneath your floors or roof. When comparing options, make warranty length and conditions part of your decision because quality underlayment should last as long as the surface above it.

ROBERTS First Step Premium Underlayment – 630 sq. ft. Roll – 40″ x 189′ x 2 mm

ROBERTS Black Jack Underlayment – 100 sq. ft. Roll – 43″ x 28′ x 2.5 mm

QuietWalk Laminate Flooring Underlayment with Attached Vapor Barrier Offering

3in1 Vapor Barrier Flooring Underlayment w/Overlap and pre-Attached Tape Strip

BlueStep Underlayment with Moisture Barrier for Laminate and Wood Floors, (200 sq.ft Roll)